Most Popular Products

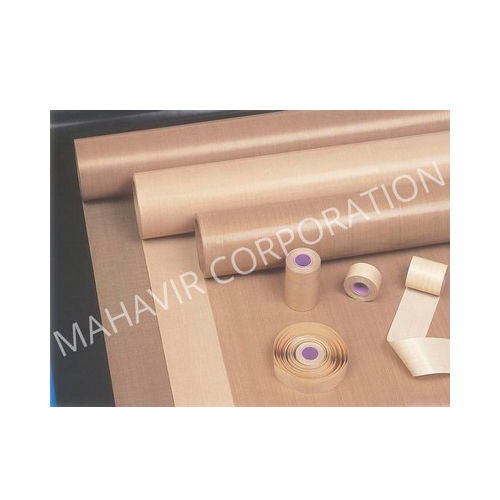

PTFE Coated Fiberglass Fabrics

PTFE Coated Fiberglass Fabrics Specification

- Glass Type

- E-Glass

- Coating Type

- PTFE

- Shape

- Roll, Sheet

- Temperature

- -170C to +260C Celsius (oC)

- Usage & Applications

- Heat sealing, insulation, conveyor belts, release sheets

- GSM

- 35 gsm to 1500 gsm

- Density

- 2.1 Gram per cubic centimeter(g/cm3)

- Thickness

- 0.08 mm to 1 mm Millimeter (mm)

- Usage

- Industrial and outdoor

- Material

- PTFE

- Size

- Different Size Available

- Application

- Industrial and outdoor

- Product Type

- PTFE Coated Fiberglass Fabrics

- Technique

- Woven

- Surface Treatment

- PTFE Coated

- Tensile Strength

- Excellent tensile strength

- Color

- Grey, Brown, Black, White

- Adhesion

- Non-adhesive or adhesive backed

- Flexibility

- Highly flexible and conformable

- Chemical Resistance

- Outstanding resistance to chemicals

- Surface Finish

- Smooth non-stick

- Electrical Properties

- High dielectric strength

- Water Absorption

- Zero water absorption

- Fire Resistance

- Flame retardant

- UV Resistance

- Excellent UV and weather resistance

PTFE Coated Fiberglass Fabrics Trade Information

- Minimum Order Quantity

- 100 Pieces

- FOB Port

- Ahmedabad

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10000 Pieces Per Week

- Delivery Time

- 3 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About PTFE Coated Fiberglass Fabrics

PTFE RELEASE AND TRANSPORT SHEET/BELT FOR SOLAR PANELLAMINATOR In solar lamination process when laminator press the solar photovoltaic modules, PTFE COATED FIBERGLASS FABRIC SHEETS are place on TOP AND BOTTOM of photovoltaic modules as a cover cloth and backing cloth, its non-stick surface help to prevent melted EVA film to stick to rubber plate and heating plate of laminator. OurRelease sheets and transport sheet have a high level of PTFE COATING , This ensure ultimate performance and multiple cycles before they need to be change. Our Sheets can be made with attachment loop in one or both ends as specified by customers.Exceptional Durability and Flexibility

PTFE Coated Fiberglass Fabrics maintain excellent tensile strength and flexibility, ensuring they perform reliably even under mechanical stress. Their conformability allows for easy installation and seamless adaptation to complex surfaces, making them a preferred choice for heat sealing and conveyor belt applications.

Innovative Non-Stick and Flame Retardant Properties

The smooth PTFE coating provides a non-stick surface, preventing adhesion of other materials and facilitating quick release, while the inherent flame retardancy increases safety in high-temperature and hazardous environments. This combination extends the lifespan of the fabric and expands its application potential.

Outstanding Chemical and Weather Resistance

Resistant to harsh chemicals and extreme weather, these fabrics offer longevity and consistent performance both indoors and outdoors. Their excellent dielectric strength and UV resistance make them ideal for electrical insulation and industrial settings exposed to fluctuating climate conditions.

FAQs of PTFE Coated Fiberglass Fabrics:

Q: How are PTFE Coated Fiberglass Fabrics typically used in industrial applications?

A: These fabrics are widely used for heat sealing, conveyor belts, release sheets, and electrical insulation due to their exceptional non-stick surface, flame retardancy, and resistance to chemicals and high temperatures.Q: What benefits does the PTFE coating provide to fiberglass fabrics?

A: The PTFE coating imparts a smooth, non-stick finish that resists chemicals, water, and UV exposure. It greatly enhances durability, thermal insulation, and ease of cleaning, making the fabric suitable for demanding industrial conditions.Q: When should I choose adhesive-backed PTFE Coated Fiberglass Fabric over the non-adhesive type?

A: Adhesive-backed versions are ideal when easy and quick installation or repositioning is needed, especially on complex surfaces or during maintenance, while non-adhesive types are preferred for heavy-duty, high-temperature applications.Q: Where can PTFE Coated Fiberglass Fabrics be utilized?

A: They are suitable for use in factories, industrial processing lines, outdoor installations where UV and weather resistance are required, and anywhere requiring high performance under thermal or chemical stress.Q: What is the process for manufacturing these fabrics?

A: PTFE Coated Fiberglass Fabrics are produced by weaving E-Glass yarns into fabrics, followed by a surface treatment where a PTFE coating is applied. This process ensures an even, robust finish with excellent mechanical and chemical properties.Q: What thickness and size options are available for these fabrics?

A: These fabrics come in thicknesses ranging from 0.08 mm to 1 mm, with customizable dimensions available in both roll and sheet form to meet specific application requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Fiberglass Fabrics Category

High Silica Fiberglass Fabric

Price 750 INR / Unit

Minimum Order Quantity : 100 Units

Material : Polyester

Usage : Industrial and Outdoor

Size : Different Size

Color : Brown

Silicon Rubber Coated Fiberglass Fabrics

Price 600 INR / Unit

Minimum Order Quantity : 100 Units

Material : Silicon

Usage : Industrial and Outdoor

Size : Different Size

Color : Multicolor

PTFE Coated Fiberglass Fabrics

Price 600 INR / Unit

Minimum Order Quantity : 100 Units

Material : Silicon

Usage : Industrial and Outdoor

Size : Different Size

Color : Brown

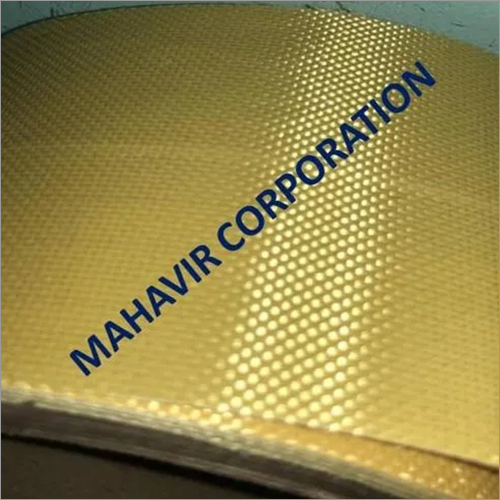

PTFE Coated Kevlar Fiberglass Fabric

Price 1200 INR / Unit

Minimum Order Quantity : 100 Units

Material : Polyester

Usage : Industrial and Outdoor

Size : Different Size

Color : Yellow

|

MAHAVIR CORPORATION

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |